In this post, we’ll detail every step Roger Wakefield takes as he removes a rusted old sink, installs a brand-new one, and integrates a garbage disposal into the setup. We’ll also discuss how a partner like Ferguson can streamline getting the tools and fixtures you need, and why thorough preparation makes the difference between a seamless replacement and a messy job.

Even if you plan to eventually replace your countertops or add a garbage disposal later, it’s often simpler to set up your new sink right away—especially if the old one is damaged or outdated. As you follow along, keep an eye out for a subtle installation “gotcha” that Roger teases in the video (hint: pay attention to the sink drain alignment). By the end, you’ll see exactly what might be wrong, how to avoid it, and how to ensure your own project meets high-quality standards.

Below is a step-by-step walk-through of the entire process, from removing the old sink and cleaning the counter, to installing the faucet, hooking up the water lines, and testing for leaks. Let’s dive in.

1. Preparing the Countertop and Work Area

A. Assessing the Old Sink

- Why Replace? The original sink in Roger’s video was rusty, pitted, and simply unattractive. Corrosion around the edges can mean water seeps beneath the rim, causing mold or countertop damage.

- Check the Countertop: Whether you have laminate, tile, or stone, be sure your new sink covers any cutouts or uneven spots left by the old sink. Take note of any damage—like cracked laminate—that you might repair or hide with the new sink’s rim.

B. Removing the Old Sink

- Shut Off Water: Always start by turning off the hot and cold water supply valves beneath the sink. If they’re corroded or stuck, you may need to turn off the main water supply temporarily.

- Disconnect Supply Lines: Use an adjustable wrench or channel-lock pliers to loosen and remove the hot and cold lines from the faucet base.

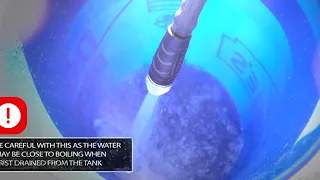

- Detach Drain and Disposal (If Present): Unscrew the P-trap or tailpiece, carefully draining residual water into a bucket. If a garbage disposal is installed, unplug it and twist or unclip it from the mounting bracket.

- Loosen Sink Clips: Beneath the sink, you may find small metal clips that fasten the sink rim to the underside of the countertop. Unscrew or unclip them.

- Cut Away Old Caulk or Sealant: If the sink rim was sealed to the counter, use a utility knife or putty knife to slice through the caulk.

- Lift Out the Old Sink: Gently pry up from underneath or push from below. If it’s stuck, double-check you’ve cut all the sealant and removed all clips.

C. Clean the Countertop Opening

- Scrape Residue: Old caulk or plumber’s putty can cling to the countertop edge. A razor blade or putty knife helps remove it without scratching.

- Wipe Down: After scraping, wipe with warm water or a mild cleaner to ensure the surface is smooth and dry.

2. Testing the Fit of the New Sink

A. Dry-Fit Before Assembly

- Set It in Place: Roger sets the new sink into the opening to verify it covers the old sink’s footprint. This is crucial. If the new sink’s rim is too narrow, you’ll see gaps or leftover stains from the previous installation. If it’s too wide, you’ll need to enlarge the opening.

- Check Counter Imperfections: If you notice issues, like cracks in laminate or tile, decide whether you’ll patch them or rely on the sink rim to cover them.

B. Marking Potential Adjustments

- Watch for Bent Edges: As Roger shows in the video, one corner of his new sink was slightly bent. He tapped it gently with a screwdriver and a small hammer to flatten it. This is easier to address before you secure the sink.

- Check Clearance for the Faucet: If your faucet is tall, make sure it won’t hit the backsplash or window sill.

3. Installing the Faucet and Accessories First

A. Why Pre-Install on the Sink?

Most professionals mount the faucet, sprayer hoses, and even the garbage disposal flange before dropping the sink in. It’s much easier to attach everything on a workbench than to work upside-down under a cramped cabinet.

Steps to Mount Your Faucet:

- Attach Rubber Gaskets: Many faucets come with a rubber or plastic gasket that sits on top of the sink to seal against moisture.

- Insert Faucet Through Holes: Typically, you’ll align the faucet’s mounting shank(s) with the sink holes. If your faucet includes a side sprayer or separate handles, follow the specific instructions and line up each piece correctly.

- Secure Underneath: From below, slip on the metal and/or rubber washers, then thread on mounting nuts. Tighten them so the faucet doesn’t wiggle, but avoid over-tightening to prevent damaging the sink.

- Double-Check Orientation: If the faucet handle can be placed to the left or right, decide your preference. Also confirm the spout is centered over the sink basin.

Installing a Pull-Down Sprayer:

- Attach the Weight: Pull-down sprayers rely on a weight clipped onto the hose underneath the sink to retract the nozzle. Position it on the hose where it won’t bump into plumbing.

- Check for Smooth Retraction: Test how the hose slides in and out. Adjust the weight if it snags on supply valves or cabinet features.

4. Mounting the Garbage Disposal Flange

If you’re installing a garbage disposal, the top portion that clamps to the sink (often called the disposal flange and mounting assembly) typically includes:

- Sink Flange: This is what you see on the top side.

- Rubber Gasket: Goes under the flange, contacting the sink.

- Mounting Hardware: Screws, snap rings, and a triangular or circular metal bracket that tightens against the underside of the sink.

Key Points:

- Use Plumber’s Putty or Silicone: A small ring of putty around the sink flange helps seal against leaks. If your manufacturer recommends silicone, follow their guidance.

- Tighten Evenly: When you snug up the screws, do so in a pattern so the flange seats evenly, squeezing out any excess putty.

5. Securing the New Sink

A. Caulk or Plumber’s Putty?

For stainless-steel drop-in sinks, many installers use a thin bead of silicone caulk around the rim to keep water from leaking under the lip. Roger chooses to apply a bead after the sink is in place, but you could also apply it just before dropping the sink if you have enough control to avoid smearing it everywhere.

B. Sink Clips

- Assemble the Clips: The sink likely comes with L- or Z-shaped clips that grab onto the rim from underneath.

- Position the Clips: Spread them around the sink’s perimeter, focusing on corners and spaced intervals along each side.

- Tighten Evenly: Start each clip by hand, then tighten with a screwdriver. Alternate sides to pull the sink down evenly. Watch that the sink lip remains flush with the countertop.

C. The Mystery “Gotcha”

In Roger’s project, something is off about the sink’s offset drain. He mentions the disposal’s J-bend can’t reach properly if the sink’s drain is too far from center. By adding a garbage disposal, he can shift the drain alignment. This is a clue that you should always confirm your new sink’s drain location suits your existing plumbing rough-in. If the drain outlet is offset too far from your old drain line, you might have to rearrange piping or add extension tubes.

6. Reconnecting Supply Lines

A. Water Supply

Often, new faucets come with flexible supply hoses. If the hoses aren’t long enough, you can add brass or steel-braided extenders—make sure they have the correct compression fittings. Here’s how to do it:

- Thread the Hose onto the Faucet’s Tail: This is typically a 3/8-inch compression.

- Attach the Other End to the Shutoff Valve: If your valve is a 3/8-inch compression outlet, you’re good to go. Snug it up with an adjustable wrench, but don’t overtighten.

- Use the Right Washers: Ensure any washers required for a good seal are in place. Some hoses have built-in washers; others might require Teflon tape. Read the instructions.

B. Testing for Leaks

After hooking up the hoses, turn on the shutoff valves slowly. Watch for drips around the faucet connections or at the angle stops. Wipe them with a paper towel; if you see any moisture, tighten gently until the leak stops.

7. Installing and Wiring the Garbage Disposal

A. Disposal Basics

If you have a dishwasher, you’ll likely attach its drain hose to the disposal’s inlet. Remember to knock out the plug inside that inlet so the dishwasher can drain.

- Hang the Disposal: Line up the disposal’s collar with the mounting bracket on the sink flange. Some disposals twist on; others clamp.

- Knock Out the Dishwasher Plug: If you skip this step, your dishwasher can’t drain into the disposal. Use a hammer and screwdriver to break the plug, then fish out the plastic piece inside the disposal.

- Tighten the Disposal: Insert a tool (like a small screwdriver or disposal wrench) into the disposal ring for leverage and twist it until it locks in place.

B. Electrical Connection

- Hardwired vs. Plug-In: Some disposals are wired directly (hardwired) while others plug into an outlet under the sink. If you have a dedicated disposal outlet, simply plug it in. If wiring direct, follow the manufacturer instructions for safely connecting black, white, and ground wires inside the disposal’s access panel.

8. Hooking Up the Drain

A. Tailpiece or Disposal Outlet

- Rubber Gasket: Most disposals come with a rubber gasket where the drain outlet pipe attaches. Slide it into place, then tighten the metal flange or clamp.

- Positioning the Trap: If the disposal’s outlet is higher or differently offset than your old sink’s drain, you may need to adjust or replace the existing P-trap or tailpiece. In the video, Roger cuts a small extension piece to make everything align neatly.

B. Double Check for Center Alignment

If your sink drain is offset and your disposal’s standard J-bend can’t shift enough, you might need a flexible extension or a different disposal with a different outlet angle. Roger overcame this by placing the disposal in a spot that ensures the short drain line can meet the P-trap properly.

9. Final Testing and Clean-Up

A. Fill the Sink

- Plug the Drain: Fill the basin with water to check the sink’s structural integrity and confirm the rim is sealed.

- Release Water: Unplug the drain and watch under the sink for any sign of leaks around the tailpiece, P-trap connections, or disposal inlet.

B. Disposal Check

- Run Water: Turn the faucet on to ensure a steady flow.

- Switch on Disposal: Listen for unusual grinding or squeaking. If the disposal sounds labored or you notice water splashing out, something may be blocked or misaligned.

C. Inspect for Drips

Look carefully at all plumbing connections—water supply lines, disposal mounting clamp, and drains. Use your fingertips or a paper towel to detect tiny leaks. Even a slow drip can cause damage over time, so tighten fittings if needed.

10. Common Pitfalls to Avoid

- Skipping the Dry-Fit: Always test your new sink in the existing hole before making final attachments.

- Forgetting the Dishwasher Knockout: If the plug remains in the disposal, your dishwasher will back up.

- Underestimating Sink Clips: Make sure you have enough clips and position them evenly to prevent corners from lifting.

- Misaligned Drain: If your old drain lines and new sink’s drain hole don’t match, plan for extra fittings or choose a sink that’s similarly aligned to your old one.

- Over-Tightening: Whether it’s the faucet mounting nut or the P-trap slip-joint, watch out for cracking or stripping threads if you apply too much force.

11. Why Partner with Ferguson?

Throughout the video, Roger mentions that Ferguson is the go-to source for his plumbing supplies. Here’s why:

- Large Inventory: From faucets and sinks to disposals and specialty fittings, Ferguson stocks a wide range of plumbing products.

- Professional Support: Their team knows plumbing—so if you’re tackling an advanced job, you can get advice to select the right fixtures and materials.

- Online Convenience: You can order parts for delivery, or coordinate with a local branch to pick up your items quickly. This is invaluable if you discover mid-project that you need an extra adapter or a different drain kit.

For experienced plumbers and first-time DIYers alike, having a reliable supplier reduces stress and ensures you use quality components that last.

Conclusion

Replacing a kitchen sink can be a day’s project for the motivated DIYer or an easy job for a professional plumber—provided you do your homework, use proper tools, and gather the right materials. In How to Replace Your Kitchen Sink | Plumbing 101, we saw Roger transform a rusty, outdated sink into a fresh, clean workspace complete with a garbage disposal. While he teased an underlying “mistake” related to the offset drain location, the fix was made possible by carefully placing the disposal and customizing the drain piping.

Here are the key takeaways for a successful kitchen sink replacement:

- Plan Before You Start: Choose a sink that covers the existing counter cutout and lines up well with your plumbing.

- Install Accessories First: Mount the faucet, disposal flange, and drain hardware on the sink while it’s still out of the counter—this spares you a lot of awkward under-sink maneuvering.

- Use Quality Materials: Leaky connections and rusted parts often stem from cheap fixtures. Investing in decent faucets, disposal units, and supply lines pays off long-term.

- Secure and Seal: Make sure sink clips are tight and the rim is sealed with either silicone or plumber’s putty, depending on your preference and sink material.

- Test Thoroughly: Running water at full blast, filling the sink, and checking all joints is crucial to ensure no hidden leaks crop up.

Armed with these steps—and a willingness to get hands-on—you can replace your own kitchen sink confidently. And remember, if you run into tricky plumbing questions, or need specialty items, Ferguson is a proven resource for quality products and expert guidance.