What Does Coke Do To Your Pipes? This intriguing question addresses the potential impact of acidic beverages like Coca-Cola on various types of plumbing pipes. While Coke is a popular drink enjoyed by millions, its acidic nature raises concerns about its effects on household plumbing systems. In this comprehensive guide, we’ll delve into an experiment that tests the effects of Coke on different pipe materials, analyze the results, and provide insights into maintaining a healthy plumbing system.

1. Introduction

Plumbing systems in homes are constructed using a variety of materials, each with its own resilience to different substances. Understanding how everyday items like beverages can affect these materials is crucial for preventing costly repairs and maintaining the integrity of your home’s plumbing. This guide explores an experiment where Coke was applied to various pipe types to assess its impact, offering valuable lessons for homeowners and plumbing professionals alike.

2. Understanding Pipe Materials and Their Vulnerability to Acidity

Different pipe materials respond uniquely to acidic substances. Here’s a breakdown of common plumbing materials and their susceptibility to acidic damage:

a. Cast Iron

Cast iron pipes are known for their durability and longevity. However, their surfaces can be prone to corrosion when exposed to acidic substances over time.

b. Steel

Steel pipes, especially those coated with protective layers, offer strong resistance to many chemicals. Yet, prolonged exposure to acids can still lead to rust and weakening of the pipe structure.

c. Chrom-Plated Brass

Chrom-plated brass combines the strength of brass with a protective chrome coating. While the plating offers some resistance to corrosion, the underlying brass can degrade when exposed to strong acids.

d. Copper

Copper pipes are highly resistant to corrosion and are generally durable. However, excessive exposure to acidic substances can cause pitting and surface damage.

e. PVC and ABS

Polyvinyl Chloride (PVC) and Acrylonitrile Butadiene Styrene (ABS) pipes are plastic-based and exhibit excellent resistance to most acids, making them less vulnerable to acidic damage compared to metal pipes.

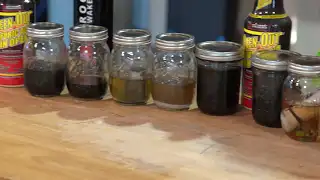

3. The Experiment: Testing Coke on Various Pipe Types

In this experiment, Coke was used to simulate the effects of acidic exposure on different pipe materials. The following pipe types were tested:

- Cast Iron

- Steel

- Chrom-Plated Brass

- Copper

- PVC (Schedule 10)

- ABS

- Rubber Hose

- Dishwasher Hose

- Galvanized Pipes

The objective was to observe any changes or damage over a 60-day period after applying Coke to each pipe type.

4. Results and Observations

After 60 days of exposure to Coke, each pipe type was examined for signs of damage, corrosion, or any other changes.

a. PVC vs. Coke

PVC pipes showed minimal to no signs of damage. The chemical composition of PVC makes it highly resistant to acidic substances like Coke, maintaining its integrity throughout the experiment.

b. Steel Pipe vs. Coke

Steel pipes exhibited slight rusting and surface roughness, particularly around the threaded areas. While not severely damaged, the rust indicates that prolonged acid exposure can weaken steel pipes over time.

c. Dishwasher Hose vs. Coke

The dishwasher hose, typically made of rubber, remained largely unaffected. The flexibility and material composition of rubber hoses offer good resistance against acidic substances.

d. Rubber Hose vs. Coke

Similar to the dishwasher hose, standard rubber hoses showed no significant damage, maintaining their flexibility and functionality.

e. Schedule 10 PVC vs. Coke

Schedule 10 PVC pipes, known for their thinner walls, remained intact with no visible signs of wear or damage, underscoring PVC’s resilience to acidic exposure.

f. ABS Pipe vs. Coke

ABS pipes showed no noticeable damage. Like PVC, ABS is a plastic-based material with excellent resistance to acids, ensuring durability even under prolonged exposure.

g. Chrom-Plated Brass vs. Coke

Chrom-plated brass pipes displayed some discoloration and minor surface erosion. While the chrome plating provided a protective barrier, the underlying brass showed early signs of corrosion.

h. Copper vs. Coke

Copper pipes maintained their appearance with no significant pitting or surface damage. Copper’s natural resistance to corrosion makes it a durable choice, even when exposed to acidic substances.

i. Cast Iron vs. Coke

Cast iron pipes showed some surface rusting and minor cracks, particularly around joints and fittings. The acid in Coke can accelerate corrosion in cast iron over extended periods.

j. Galvanized vs. Coke

Galvanized pipes exhibited noticeable rust and corrosion, especially along the threaded connections. The zinc coating, while protective, began to degrade under acidic exposure, leading to increased vulnerability.

5. Analyzing the Impact of Coke on Pipes

The experiment reveals that the impact of Coke on plumbing pipes varies significantly based on the material:

- Highly Resistant Materials: PVC, ABS, and rubber hoses showed exceptional resistance to acidic exposure, remaining unaffected after 60 days.

- Moderately Resistant Materials: Copper pipes maintained their integrity, while chrom-plated brass showed minor surface erosion, indicating that these materials can withstand acidic substances but are not entirely immune.

- Less Resistant Materials: Steel, cast iron, and galvanized pipes exhibited signs of rust and corrosion, highlighting their vulnerability to prolonged acidic exposure.

6. Conclusion: Is Coke Bad for Your Plumbing?

Based on the experiment’s findings, Coke does have some detrimental effects on certain pipe materials, particularly those made of steel, cast iron, and galvanized coatings. While plastic-based pipes like PVC and ABS, as well as rubber hoses, are highly resistant to acidic substances and show no significant damage, metal pipes are susceptible to corrosion and rust when exposed to acids over time.

Key Takeaways:

- Avoid Pouring Acidic Beverages: To protect your plumbing system, refrain from pouring acidic beverages like Coke down your drains. The acidity can accelerate corrosion in metal pipes, leading to leaks and structural damage.

- Regular Maintenance: If your plumbing system uses metal pipes, regular inspections and maintenance are crucial to identify and address any early signs of corrosion or leaks.

- Consider Pipe Material: When planning plumbing installations or renovations, consider the longevity and resistance of different pipe materials to various substances to ensure a durable and reliable system.

7. Preventative Measures to Protect Your Plumbing

To safeguard your plumbing system from acidic damage and other potential issues, consider the following preventative measures:

a. Choose Resistant Pipe Materials

Opt for PVC or ABS pipes in areas where chemical exposure is likely, as these materials offer superior resistance to acids and other corrosive substances.

b. Install Protective Coatings

For metal pipes, applying protective coatings or sealants can provide an additional barrier against acidic substances, reducing the risk of corrosion.

c. Educate Household Members

Ensure that everyone in the household understands what can and cannot be poured down the drains. Avoid disposing of non-biodegradable items and limit the intake of acidic beverages that may enter the plumbing system.

d. Regular Plumbing Inspections

Schedule routine inspections with a professional plumber to identify and address any signs of corrosion, leaks, or other plumbing issues before they escalate into major problems.

e. Use Drain Strainers

Install drain strainers to catch debris and prevent clogs, which can lead to leaks and increased wear on your plumbing system.

8. FAQs

Q1: Can other acidic beverages like orange juice or vinegar damage pipes?

A: Yes, other acidic substances can similarly affect metal pipes by accelerating corrosion and rusting. It’s best to avoid pouring any acidic liquids down the drains.

Q2: Are there any permanent fixes for temporary leaks caused by acidic exposure?

A: Yes, replacing or relining the affected sections of pipes is recommended for a long-term solution. Consulting a professional plumber is advisable for such repairs.

Q3: How often should I inspect my plumbing system for signs of corrosion?

A: Regular inspections every 1-2 years can help detect early signs of corrosion and prevent extensive damage.

9. Final Thoughts

While Coke may not be the first thing that comes to mind when considering plumbing maintenance, its acidic nature can have unforeseen consequences on certain pipe materials. Understanding the materials used in your home’s plumbing system and taking proactive measures to protect them is essential for avoiding costly repairs and ensuring the longevity of your plumbing infrastructure.

By choosing resistant pipe materials, practicing regular maintenance, and educating household members on proper disposal practices, you can maintain a healthy and efficient plumbing system. Remember, prevention is always better than cure, and taking care of your pipes today can save you from significant headaches tomorrow.